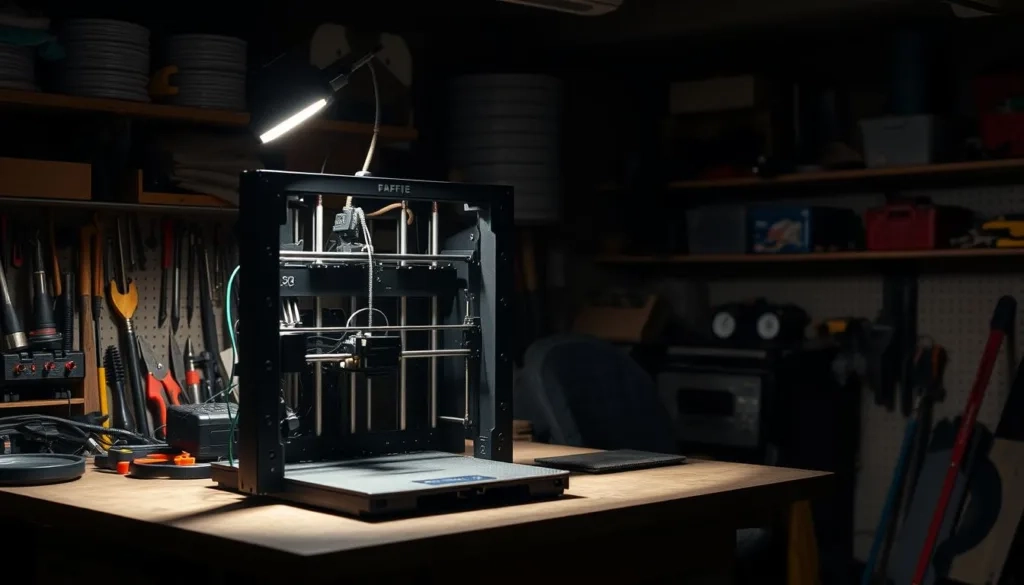

In recent years, 3D printing has changed the game in garage-based manufacturing. It uses digital fabrication to let people and small businesses make custom products at home. With 3D printers costing under $2,000, anyone can turn ideas into real prototypes quickly and affordably.

Now, making complex designs with materials like ABS plastic is easy. This has sparked a maker movement. Hobbyists and entrepreneurs can now test ideas fast, cutting down the time to market from years to months. As 3D printing gets better and more people can use it, the market is expected to grow to $35.6 billion by 2024. This shows a big change in how we see making things and being creative.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a way to make three-dimensional objects. It uses digital models and layers materials to create them. This method is different from traditional ways of making things, which often involve cutting out parts from a solid block.

The 3D Printing definition includes many technologies. These range from Fused Deposition Modeling (FDM) to Stereolithography (SLA). They all help make detailed designs with little waste.

The history of 3D printing started in the 1980s with Chuck Hull’s invention of stereolithography. Since the 2010s, it has become more common. At first, 3D printers were very expensive, costing hundreds of thousands of dollars. Now, they are more affordable, making additive manufacturing available for home use and small businesses.

Today, 3D printing is used in many fields like automotive, aerospace, and healthcare. Companies like Ford and GE use it to make their production faster. For instance, GE made a big change by using 3D-printed fuel nozzles in their LEAP engine. This reduced the number of parts from twenty to one and cut down on weight.

The Garage Revolution: Why 3D Printing Matters

3D printing has changed the game for garage makers. It lets people with big ideas make them real. This tech lets hobbyists and small businesses create things big companies used to have a monopoly on.

It makes it fast to go from idea to product. This quick turnaround inspires more people to try making things. It’s a chance to see their ideas come to life.

This change is big for making things. Old rules are being broken. Now, anyone can make custom items without spending a lot. Small businesses can compete with big names by offering unique products from their own space.

How 3D Printing Works: The Basics

The layering process is key in 3D printing. It involves adding materials layer by layer until a full object is created. This method lets us make detailed designs based on a digital plan.

Many materials are used in 3D printing, loved by both hobbyists and experts. Plastics like PLA and ABS are common, known for their flexibility and simplicity. There are also metal powders, flexible filaments, and biocompatible materials for medical use. This variety shows the endless possibilities in 3D printing.

There are different types of 3D printers, each with its own strengths. FDM printers are great for making prototypes and models. SLA printers are best for fine details and quick production. DLP printers work even faster, and SLS printers use lasers to fuse powdered materials.

Cost Effectiveness of 3D Printing

3D printing is a cost-effective way to make things. It’s different from traditional methods that need expensive tools. With 3D printing, you can start making things right from digital files.

This method is great for quick prototypes. It helps companies find and fix mistakes before making lots of products. For example, a single 3D printed nozzle can replace 20 old parts. It’s lighter and lasts longer, saving 30% compared to old ways.

This shows how 3D printing can save money. It makes it easier for new businesses to start. They don’t have to spend a lot on tools or big inventories.

It’s a way for small businesses to compete. They can make unique products fast and cheap. This is true in fields like digital dentistry, where custom items can be made quickly and affordably.

Designing for 3D Printing

Designing for 3D printing means knowing what software tools can do. Tinkercad is a free, web-based tool great for beginners. It has many tutorials to help learn 3D modeling basics.

Tinkercad works well with 3DPrinterOS. This lets designers manage their prints and check if models can be printed.

Following best practices in 3D modeling is key for quality prints. It’s important to keep wall thickness right. Walls should be two to three times the nozzle width.

For a 0.4 mm nozzle, walls should be over 0.8 mm thick. This makes prints more durable. Also, details like overhangs need attention. Overhangs over 45 degrees need supports for printing.

Layer height is also crucial for quality prints. Keep it at 80% or less of the nozzle diameter. Smaller nozzles are better for detailed designs. Larger nozzles make printing faster without losing material flow.

After printing, sanding or painting can make prints look and work better. This step is vital for many designers.

Challenges of Garage-Based 3D Printing

3D printing in a garage faces many hurdles beyond just setting it up. One big issue is the technology’s limits. Most 3D printers need a steady temperature, between 20-25°C (68-77°F), to work well. If the temperature gets too high or low, it can mess up the printing.

Another problem is the environment. Too much humidity can make filaments absorb moisture, leading to 20-30% more defects. This makes it crucial to have good air quality in your garage. Using filters can help keep the air clean and improve print quality.

Regulations also pose a challenge, mainly in fields like healthcare. Following strict safety rules can be a big obstacle. These rules can make it hard for small businesses and individuals to use 3D printing fully.

Success Stories of Garage-Based Manufacturers

Garage-based manufacturers are now key players in the 3D printing world. They show how creativity and technology can lead to amazing products. Impressão 3D Portugal is a great example. It started in a garage with just two printers and has grown into a leading custom manufacturer in Portugal.

Impressão 3D Portugal runs the biggest 3D printing farm in the country. They can make parts in huge numbers, from 500 to 5,000 units. They use top-notch Original Prusa MK3 printers and plan to upgrade to MK4 soon. They also use augmented reality glasses for real-time monitoring.

Crazy Grandpa’s Garage is another example of success. They’ve grown their printer fleet to meet demand for custom parts. Their approach to scaling has greatly reduced costs and turnaround times. For instance, they’ve cut costs by 50% and now make custom car parts in just 5 days, down from 30.

The stories of these makers highlight the power of 3D printing. It allows for creating innovative products without the usual manufacturing hurdles. These success stories inspire others to try 3D printing in their own garages.

The Future of 3D Printing in the Garage

The future of 3D printing in garages is bright. New technologies will let homeowners build and customize things in new ways. They can make detailed designs and stronger parts, perfect for new or old projects.

The car world is also changing thanks to 3D printing. Big car companies are starting to use it, but there’s still a big gap. Car fans are now making their own parts, which is helping with old car fixes.

In places like Europe and Japan, 3D printing is a big help. It lets people find parts they need. For example, a part that used to cost $2,000 now costs $750. This shows how 3D printing can save money and make things better.

Building garages will also get a boost from 3D printing. It’s faster than old ways, taking days instead of weeks or months. This means you can make your garage unique and strong. Even though it costs a lot at first, it’s worth it for the savings and less waste.

Community and Collaboration in 3D Printing

3D printing communities are key in making technology accessible to all. They use online forums and social media to share knowledge. Sites like Reddit are great for exchanging tips and showing off projects.

Local maker spaces are also important. They offer tools like 3D printers for creative people. Workshops there let you learn by doing, which is very helpful.

Groups like Prusa and RepRap show how teamwork can improve 3D printing. They work on open-source projects, sharing designs and resources. This helps everyone in the community grow and innovate together.

In short, working together in 3D printing makes things better and faster. Whether it’s through local spaces or online, collaboration is key. It helps everyone learn and grow, shaping the future of 3D printing.

Sustainability and 3D Printing

Sustainability in 3D printing is key for the future of making things. It uses eco-friendly materials like bioplastics and recycled composites. This helps reduce harm to the environment.

Using these materials, companies can cut their carbon emissions a lot. This is because traditional methods use a lot of energy and create a lot of waste.

3D printing stands out because it reduces waste in making things. Unlike old methods, it only uses what’s needed. This saves money and helps the planet, which is good for businesses and the environment.

Companies like Vestas show how 3D printing can help. They store digital files for parts, cutting down on logistics and inventory. This saves energy and reduces waste.

By 2050, 3D printing could save up to 90% of raw materials. This is a big step forward for making things better for our planet.

More people want to buy things that are good for the environment. This means businesses can make more money by being green. Being eco-friendly can also help a company’s bottom line.

Getting Started with 3D Printing at Home

Starting with 3D printing at home is both exciting and rewarding. The first step is choosing the right equipment. There are many printers for beginners out there.

Models like the Creality Ender 3 and Prusa Mini are great for beginners. They are reliable, easy to use, and have a big community of users. This makes them perfect for those new to 3D printing.

After picking a printer, it’s time to start your first project. Choose something simple to learn the basics. Make sure your printer is set up right and learn the software.

Don’t worry if you make mistakes at first. Trying and learning from errors is part of getting better. Most beginner printers print at about 100 milliliters per minute. The time it takes to print depends on the object’s size and how dense it is.

Also, try out different materials to improve your experience. PLA is a favorite because it’s made from plants and is good for the environment. But, it can’t be recycled with regular plastics.

As the 3D printing world grows, getting into it now is a smart move. It opens up a world of creativity and puts you ahead in a growing market. By 2024, the industry is expected to be worth over $40 billion.